The Bagpipe Society

A slow boat to Sweden: creating my säckpipa over a mere twenty-seven years...

I first came across the Swedish bagpipe (säckpipa in Swedish) in 1990, when I was staying with my friend Joachim von Usslar in Hamburg. We had met on the London College of Furniture’s Early Woodwind course and, several years after we finished, I went to work with him for a month in his basement workshop. Jo had become a fantastic street entertainer and found the living much better than being a maker, so he employed me to do some turning to complete some orders, even though I hadn’t set up as a maker myself at that point and hadn’t turned anything for three years. So, I found myself in a basement in a suburb of Hamburg turning the various fairly simple parts of the säckpipa, sharing the space with stilts, escapology equipment, fresh horsetails (for making bizarre hairy, scary costumes), and a small but fully functioning canon. My career choices will never make me rich, but they have so far led me through a far from dull lifetime.

After I finished at LCF three years earlier I followed some Finnish musicians I met in Belgium to their festival in the Finnish town of Kaustinen, not realising that the beautiful music they played was actually Swedish. I then heard the Swedish band Filarfolket at various English festivals that same year, as at the time I was working the folk circuit regularly as a self-employed musician in various bands. I fell in love with the Swedish music I heard that year, but none of it ever involved säckpipa, and I vaguely remember hearing the instrument on one track of a solo album one of the members of Filarfolket had put out, and finding it a fairly dubious instrument. However, three years later in Hamburg I remember quite liking the sound of the first instrument we put together (Jo made the reed and bag) and thinking I might like to make myself a set at some point. On my return to England I found we were in a recession and out of necessity I started working in a local music shop that specialised in woodwind repairs, and for the next three years I learnt modern woodwind repairing.

Fast forward several years and I was still chasing an uncertain “career”; studying towards a PhD in music composition at Goldsmiths College, and working as a contemporary dance accompanist at the Laban Centre, the Royal School of Ballet and the English National Ballet School. The thought of also becoming a maker at some point was still in the back of my mind, so I begged some time in my old college workshop from my old friend and one time neighbour and fellow-squatter David Armitage who was now teaching there, and I made myself a set of säckpipa from the plans I had brought back from Germany over a decade earlier. I bought a bag’s worth of leather from Jon Swayne at one of our Zephyrus rehearsals, and put the various bits together. I can’t remember where I got a small piece of cane from, but somehow I fashioned two reeds (drone and chanter) and somehow they worked reasonably well. But I didn’t really do anything with the pipes, as the sound wasn’t great, the playing pressure was weird, and I thought they were fairly ugly. Plus, they were in Eb, whereas I knew they were supposed to be in E! But I had a “working” set of pipes which at the time was all I was after.

My composition work was picking up, and in 2010 I was in the running for a £50,000 prize in the PRSF New Music Award for my proposal for a piece called Automata Musica. Basically I had suggested the idea of making lots of music boxes that could be randomly played in public places to create an ever-changing aleatoric score. I didn’t win, but as part of the preparation for the award I had become an Honorary Fellow of the London Metropolitan University, which had taken over the old London College of Furniture courses, so I had full-time access to a workshop for the first time since leaving LCF in 1987. There I shared a workshop with a fantastic lute maker from Brazil called Marcos Kaiser Mori, and together we took a stall to exhibit at the London international Early Music Exhibition in Greenwich. Alongside Marcos’ beautiful theorbo, I placed an Appalachian banjo I’d made and my old set of säckpipa. I sold the banjo! However, Julian Goodacre had a stall there as well, and was being visited by a säckpipa player from Sweden who played my pipes and said they were at least as good as any he had played from the Swedish makers. Perhaps there might be a future for them?

In 2011 we moved from London to a small village in Cambridgeshire, to a very old house with a 1980s double length garage attached to one side. I slowly lost touch with my compositional contacts and the work slowed down. So I started to look for other work, returning first to repairing modern woodwind instruments on a freelance basis for a music shop in Cambridge, and gradually setting up a maker’s workshop in my garage. Finally, around twenty six years after leaving LCF I was in a situation where I could start to make my own woodwind instruments.

I returned to the instruments that I had developed at LCF to start with. I had already developed a tabor pipe in D, a wooden whistle, and a medieval recorder (which became one of the coursework instruments at LCF under David’s time) so I started with those. Then I designed tabor pipes in C and low G, and a treble and sopranino medieval recorder. I still kept away from any bagpipes at that point, as my occasional attempts to get another reed working for my säckpipa were consistently failing.

Making reeds is a strange business. In common with many of the students back in my LCF days, I happily made a reed for every new instrument I finished, and it generally worked. When our first reed broke, we would casually make another and find that it would not work. Nor would the next one, nor the next…and so on. There seems to be some mystical power that allows the first voice of the instrument be to be heard, only for it to be cruelly taken away until we are deemed to be worthy creators. One has to undertake the Herculean task of making (as Irish pipe makers put it) a “washing basket of bad reeds” before finally gaining some consistency and success.

Chance came to my rescue again in the shape of an Ebay purchase by Jane Moulder two years ago. She bought an old set of säckpipa from the early years of the folk piping revival (about 1980s) made by Leif Eriksson and she brought them to the Blowout. Previously she had seen my other set and knew I had an interest, so she kindly lent them to me: she also sent me a pdf of the plans drawn by Eriksson for this very set. The first thing that struck me was that they looked beautiful. They were simple, like the ones I had made from the German plans, but the lines were more elegant; the stocks, although fatter, suited the shortened nature of the parallel bored chanter and drone; the chanter and drone fitted into the stocks with a tapered tenon which just felt organic and natural; and the decoration consisted of a simple line of carving round each stock and wide beads on the chanter and drone. The wood was probably birch, and was unstained but oiled. It made me decide that I was going to have to conquer my fear of reed making and make this simple, beautiful pipe that appealed to my aesthetics.

A brief technical description of the instrument is due at this point. The säckpipa consists of a leather bag into which are tied three stocks

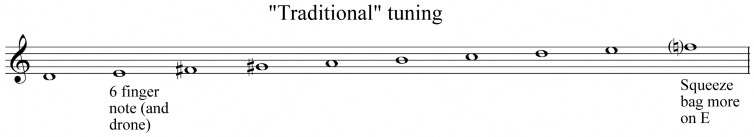

- for the blowpipe, drone and chanter. Both chanter and drone are parallel bored throughout, and each has a cane reed with a single tongue cut in the side of the cane. The drone is tunable in the usual manner, although one of the old instruments in a museum in Sweden does not have the moving slide. The chanter has seven deeply scalloped finger holes and one thumb hole at the top. The drone is tuned to the six-finger note at the same pitch, and the chanter gives the following scale:

The very top semi-tone is achieved by over-squeezing the bag to force the top E up to the high F. This usually occurs as a slurred step-wise movement in a tune; from E to F and down again.

Using the plans, I made a bag and the wooden parts of a set and then pondered the problem of the reed again. After asking round and searching on the internet, I bought 100 pieces of 6mm reed cane from a French company for 100 euros and set about fashioning some reeds. Making a drone reed was fairly straightforward, as in order to get the stability needed on the drone, the tongue needs to be a bit less flexible than on the chanter reed. There is also usually a blob of wax stuck on the tongue to keep it more stable. It means that basically, it is much easier to make, as it does not have to do as many things as a good chanter reed. The chanter on the other hand proved really difficult. I was only able to make reeds that worked well in the key of F, not E. It was only when I checked Jane’s set against a meter that I discovered that it also was in F. Jane had said she had sent the chanter off to get a reed made and that the one in it was “the best that could be done” by an experienced maker. Was it that the chanter was based on an old instrument that was in F rather than E? That threw up all sorts of other questions. After all, is there any evidence that säckpipa were played with other instruments? Would it matter what key they were in? Who made them? How widespread were they? I realised I knew very little. But then I try to be an instrument maker and not a historian of instruments, but I did form a few theories.

First, the tapered fit of the chanter and drone into the stock. Eric Moulder told me that some of the Crumhorns he measured have a tapered fit to the reed cap, which he considers a very useful thing, as it makes it very unlikely that the cap will ever get stuck on, and the reed is far less likely to get damaged. True, but thinking of a säckpipa being made in a very rural Swedish village, I wondered if there would be an “instrument maker” or whether, like the Swedish Willow Flute, it would be something that anyone with a bit of woodworking skill could make. A tapered tenon is a standard technique for fitting a turned chair leg to a solid seat (think of a Windsor chair), so a small tapered auger would be a standard village woodworking tool. Leif Eriksson was also a cabinet maker.

Second, the deep scalloping of the finger holes on the chanter has become an accepted norm for all makers of säckpipa even though we turn them on high speed lathes out of billets cut from large planks. Not so in the village I suspect. When I was in Finland in 1987 I was given a simple flute made by a chap at the Kaustinen festival. It was cut from a section of a branch of birch, roughly de-barked, and the pith poked out with a small auger. So, the external diameter of the flute was simply the diameter of the piece of branch. He cut a blowhole and made that work, then he drilled finger holes with a hand drill. All this with simple hand tools, out in the open. Then he tuned it – by scalloping the finger holes with a knife. By reducing the external diameter at the point where each finger hole was drilled he was able to sharpen each note to get it roughly in tune. Obviously he was working to some sort of mental plan (and had presumably made hundreds of these things) so that the flute was flat to start with and the tuning could only be affected upwards, but it makes me laugh now when I think of how, when I made the first five säckpipa in the Hamburg basement, I was carefully measuring the depth of each laboriously filed finger hole scallop to make them true to the set of plans.

So why do I think these things may not have been as meticulously constructed as people may like to think? I was lucky enough to be working at LCF when Kevin Rowsome was a student there. His Grandfather was the famous Uilleann pipe maker Leo Rowsome, and one day he informed us that he had got hold of, and was going to bring in his Grandfather’s tools. We had visions of exquisitely crafted heirlooms beautifully preserved, and the secrets of a great pipe maker coming within our grasp. Kevin arrived to a workshop full of would-be Irish pipe makers and David Armitage and Eric Moulder, all hoping for some great knowledge to be revealed. His response was to dump a canvas tool sack onto the bench and pull out a Napoleonic pig-sticker bayonet, a file, a gouge and a piece of floor board with a groove cut in it and a bent nail over the groove. That was it. The tapered bayonet was the reamer, and the plank was the reed making bed. Things that happened to be around, and did the job in the hands of a practical man with knowledge passed on to him from his elders. We smirked, but the smirks were wiped from our faces when Kevin very quickly and efficiently made a fully working reed for his chanter from a slip of cane held down on the plank by the bent nail and worked at with a gouge and over-sized wood file.

The Swedish säckpipa player Olle Gällmo has a fantastic website on which he very generously shares his knowledge of reed making, and it was here that I found the first full description of an alternative to the usual “Spanish” reed cane that we were encouraged to use at college. Arundo donax is the Latin name for the hard reed cane that grows around the Mediterranean and is used for all modern woodwind reeds, and is also used by most pipe makers. However, the säckpipa has a single reed in both chanter and drone, and in old-time Sweden, the usual reed cane used was that which grew locally, the Latin name for which is Phragmites australis. This reed cane also grows in most other Northern European countries, and there is plenty of it to be found here in East Anglia. I paid a premium for my small bore French reed cane (it grows to very large diameter, as normally used for modern woodwinds), yet the local cane only gets to around 8mm diameter, so finding pieces around 6mm is fairly easy. I find it quicker and easier to make a reed using the local cane. The wall is quite thin, so once you cut the tongue, there is no scraping to be done, and once you know the dimensions you are trying to work to and have some experience with manipulating the hair and bridle, it is usually possible to get the pieces sounding. The greatest freedom that using local cane has given me though is that every time I fail, I am not throwing away one euro’s worth of cane!

So now I make säckpipa, and only make chanter reeds using local cane. It is very similar to the Eriksson model, but I have moved a couple of holes around and changed some of the external shaping. I have also taken a much more open approach to the shaping of the fingerhole scallops. By simply leaving more wood on in the early stages, I have overcome the problem of reeds wanting to play in F and I do most of my tuning by undercutting the holes or increasing the depth of the scallop to sharpen, or by using wax to reduce the size of finger holes to flatten. I find that every reed I make works differently on a chanter, so I do have to re-tune a chanter each time a new reed is made. I could try to develop a plastic reed, but my two attempts so far have sounded horrible! I much prefer the sound of the local cane, and I also prefer to make my pipes in the “traditional” tuning (as shown above). I have also made a couple of sets with the extra “modern” holes that allow a greater number of tonalities and they have worked well. My future plans for the instrument involve a set in D, possibly with a single key to extend the range up a tone; a bass drone one octave lower than the standard drone as an alternative option; and the possibility of using bellows. I also want to make some “medieval” double chanter pipes based on the single reed chanter using a particular Cambridgeshire church bagpipe carving for the design, and made out of local Fens alder. Local wood and local cane for local bagpipers!

- Data Processing Notice (GDPR)

@BagpipeSociety on X (formally known as Twitter)

TheBagpipeSociety on Instagram

BagpipeSociety on Facebook

BagpipeSociety on Facebook

Something wrong or missing from this page? Let us know!