The Bagpipe Society

Highland Pipemaking in India

In a misguided fit of enthusiasm in 1978 my brother John bought new a set of Pakistani-made Highland bagpipes from Ray Mann, a music shop near Covent Garden, London, that specialised in unusual musical instruments. The bag was greasy, gave off a distinctive, but not entirely offensive stench and leaked like a sieve, the valve didn’t operate properly and the reeds were atrocious. Neither of us had any previous experience with bagpipes. We tried putting corks in the drones and took it in turns to squeeze some sort of noise out of the wretched thing. This usually ended in one of us hyperventilating whilst the other roared with laughter.

Since then I have retained a certain curiosity about these Scottish Highland pipes that are made in vast quantities in Pakistan and are sold throughout the world. Hundreds of foreign tourists in Edinburgh each year return to their respective homelands clutching one of these pipes in the belief that they have bought a genuine Scottish artefact. Scottish pipers treat them with mighty disdain,1. yet I have often seen photos of pipers mounted on camels or heard reports of them being played in the middle east, so they can be made to work and pipers all around the world do play them.

In 1987 I started a long correspondence with the Ireland Bagpipe Company, Raja Road, Sialkot, Pakistan, who claimed to be the finest bagpipe makers in the world and that they made Brian Boru Pipes. 2. This culminated in me ordering their best quality Brian Boru blackwood set which was basically a Highland pipe with a keyed chanter made in blackwood. The workmanship was certainly higher than the ones available in tourist shops, but I would not describe it as a high quality set of pipes.

With the advent of the internet I started receiving unsolicited advertising emails from pipe makers in Sialkot. There were dozens of different firms and they mostly seemed to operate from Raja Road. This industry is obviously a legacy from the British, as these firms also advertised kilts, army regalia and brass instruments. I have often wished to visit Sialkot to see how they are making these pipes. However, Pakistan is not a safe country for the conspicuous tourist and I became resigned to the fact that I would never have an opportunity to walk down Raja Road in this lifetime.

My son Liam has been living in India for over seven years and his wife Ann is Indian. Her father was in the Indian Army and he told me that some of the regiments use Highland bagpipes. Looking back I now realise how naïve I was when I suggested to him that these pipes must have been made in Sialkot. He was shocked at the very thought of the Indian army using anything that was made in Pakistan. I mentioned this later to Dr Peter Cooke and he told me that he had seen Indian pipemakers in 1986 in the town of Meerut and he sent me two photos. This was the real start of my quest to see if the trade still survives.

Each January I stay with Liam and Ann in Pune (Poona). I use my time there to write texts for my forthcoming tune book and take a bunch of pipe bags to sew up whilst basking in their garden. On each of my visits we try to get away for some kind of ‘jolly’. Before my trip this January Liam asked if I wanted to go to Goa or perhaps Agra to see the Taj Mahal. My instant response was that I wanted to travel to Meerut to track down the men in Peter’s photos and I appointed Liam and Ann to be my Research Assistants.

Meerut is a small military and industrial town north east of Delhi in Uttar Pradesh. It has a population of only 1.5 million and over the last 150 years has become a centre for musical instrument making in India. Uttar Pradesh has a history of political and religious unrest and there was an upcoming election in February with rioting anticipated. Nobody visits the town for touristic purposes, especially in their winter. Friends in Pune looked bewildered when we told them that we actually wanted to go there. They were possibly too polite to say that we were mad.

We flew up to smoggy Delhi and then took the 90 minute train to Meerut. The train station is out of town and in the taxi to our hotel Ann told the driver of our bagpipe mission. He took us on a slight detour through Jali Kothi,3. the street where most of instrument makers are situated. It was dusk, but as we were driven up the narrow street we got tantalising glimpses of a host of shops festooned with drums and brass band instruments.

The town was experiencing unexpected temperatures as low as 5 degrees centigrade. This may not seem bad to us, but most people seemed unprepared for the cold, especially those sleeping on the streets or, if lucky, in flimsy shanties. Groups of people wrapped up in blankets stood huddling around impromptu fires lit on the pavements. Our hotel was quite a way out of the centre of the town. It was grand, cold and appeared almost deserted.

Next morning as we sat alone in the enormous dining room having our breakfast we discussed what approach to take. I had done some internet research previously and it was clear that the instrument making business that dominates the town is Nadir Ali & Company and they advertise highland bagpipes on their website. Ann phoned them up and was told we should come to the factory and talk to Shirin Sayeed. We took an electric rickshaw to Jali Kothi, passing all the music shops once again and were left outside the impressive factory gates. At the front office we mentioned the magic word bagpipes and someone went scurrying off and returned with a parcel containing a brand-new set of Highland bagpipes elaborately wrapped in newspaper. We were then given a tantalisingly short tour around the factory. I am left with impressions of men hammering, spinning, heating, bending and soldering brass, using ancient machinery with seemingly little regard to safety. I could have spent many hours watching each process.

After this we met Shirin Sayeed, the manager of the company and we were all impressed by her calm and modest manner. Her grandfather Nadir Ali started the company in 1885. We talked about the problems that she has, as a single Muslim woman, managing a factory with about 100 male employees, and she freely admitted that her authority can often be challenged. She explained that the British army had originally imported all their own instruments but had found local workers to repair them and thus there was a business opportunity to start actually making them. These instruments then also found favour with Indian musicians for playing in wedding bands and school bands.

The business is now facing serious challenges. The workforce in this skilled trade was getting increasingly elderly and dying off and young men generally show little interest in learning it. It appears that there has been no major innovation for the past 80 years. All that they manufacture are copies of instruments which are in pre-First World War high pitch. Indian wedding bands love the brightness and volume of this pitch, but it means that the firm has no possibilities for exporting instruments, as most countries have now standardised to A=440. Thus the firm can only sell them in India, where cheaper Chinese instruments in high pitch are now being imported. And anyway wedding brass bands are falling out of favour, giving way to recorded music and DJ’s. We got the impression that there was a general lack of optimism in the firm.

I talked to her about my interest in bagpipes and showed her Peter’s photos, but she didn’t recognise anybody. She made no secret that the bagpipes manufactured in India were a poor copy of what is made in Scotland. They used to manufacture bagpipes actually in the factory premises, but when they needed more space, their pipe maker moved to a workshop nearby. She was interested in the pipes I make and the prices I charge and, with a calm and slightly cheeky smile, suggested that I send her one of them so that they can copy it!

She sent someone to get the pipemaker and while we were waiting I asked her about the brass flageolets that they advertise on their website. She said that they were not made in the factory and they only had a few left. She showed me their entire stock and told me to help myself. I chose five in various keys and she refused any payment. Some of them were the simple cane whistles that often find their way to UK. But they also had plastic bodied whistles, with wooden blocks in a whole range of keys and nicely made brass whistles with soldered blocks.

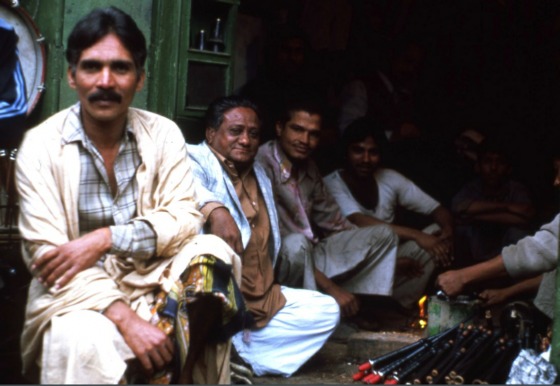

Eventually the pipe maker, Saeed Khan, arrived. When he was told we wanted to visit his workshop he looked a bit worried and said it would take a few minutes to tidy up. He must have rushed back and swept the whole place like a whirlwind because when he came back and took us to his workshop it was surprisingly tidy. We never saw any sacks of shavings, but we both enjoyed agreeing that an untidy workshop was a sign of a good workman! We were greeted by quite a gathering of men. Among them were Saeed’s three sons. The eldest, I suspect, was in his early 20s .They were keen to learn their father’s trade. We crowded into his workshop and were given chairs, which presumably had been supplied especially for us.

It was there that we spent a wonderful hour with Ann translating everything between Urdu and English. In most of my travels I have been frustrated by meeting craftsmen but not being able to communicate in any real detail and having to rely on sign language. But with Ann translating Saeed and I had the luxury of being able to talk in detail. He is a big and friendly man, possibly in his 60s and is clearly proud of his workmanship and the quality of his pipes. He told us that he was the only pipemaker in India. 4. He has been making pipes for 49 years and learnt the trade from a pipe maker from Lahore, Pakistan who migrated to Meerut before the partition in 1947.

Even though his workshop is quite small he has managed to fit in three electrically driven lathes, all at floor level. They were commercially made and might easily be 100 years old. I assume that they originally come from the Nadir Ali factory. They each had one speed only and were driven with flat belts, which, like all belts in the main factory, were totally unguarded.

I showed him Peter Cooke’s photo from 1986 and he recognised the people, but clearly was not very interested and a bit dismissive about who they were. One of his sons later informed Ann that some of them were students of his father. He showed us a completed set of his pipes with aluminium mounts and then gave us a demonstration of turning a drone stock, which he does while squatting behind the lathe which is on the floor, guiding a gouge with both his hands and big toe.5. He uses Sheesham wood, 6. I which is hard, works easily and has the colour of light mahogany. After he completed turning he gave it a good sanding and then used a double-ended scraping tool. One end is the thread-chaser which forms the combing and the other forms the low bead in between the combing. I took a video of him working. 7. He works with the effortless confidence that comes with his many years of experience. But nevertheless it was alarming to see his trouser leg dangerously flapping against the unprotected flat belt. I needed to remind myself that he has been making pipes for 49 years and has still retained two legs….

At this stage someone rushed in and kindly handed us all cups of chai, hot sweet milky Indian tea. I was videoing at the time and it was an interesting challenge to accept the tea graciously with one hand and hold the camera with the other. With the stock is still turning on the lathe he rubs on some kind of black dye. I did not ask what this was. After it has been removed from the lathe the wood will be varnished. For his higher quality pipes he uses blackwood imported from Africa. He showed me a couple of billets of rather inferior quality, which he says costs 500 rupees (£6) per kg.

He uses two types of bags, both of which are made elsewhere. He fits rubber bags 8. to his cheapest model which he supplies to schools. For the army and police he fits neatly sewn leather bags which are made locally from thin bullock leather which is light in colour. As well as making bagpipes he also makes shehnai 9. – a traditional shawm that is played in many areas of India. He makes the wooden body of the instrument, which is then fitted with a wide brass bell, presumably made at the Nadir Ali factory.

He was very proud of his new design of highland chanter. Musically speaking this is the same as his standard chanter, but he has designed and made it with narrow wooden beads in between each finger hole to strengthen the body of the chanter. 10. Apart from this I saw no sign of any ongoing development in his design of pipes. I assume he has been manufacturing the same design that he was taught to make 49 years ago.

I asked about how he bores the chanters his eldest son seemed very keen to show us. I don’t know his exact age, but you could tell by looking at the confident and meticulous way he worked that he had been doing this process for a long time. One of the lathes is set up especially for boring and reaming as there is enough room for him to squat at the tailstock end and face the chuck. 11. The chanter blank had already been turned into a rough cylinder and he took great care to centre it perfectly in the massive three jaw chuck. He then proceeded to drill half way down the bore with a 4mm drill, which he rested on a flat tool rest that was fixed at right angles to the bed on the lathe. I was impressed that a groove had formed in this steel tool rest, which must have been slowly worn down by miles of drilling over many decades. The drill bits that they use are made by him with a spear- shaped point and are very accurate and effective.

Once he had drilled half way with the 4mm drill, he switched off the lathe and reversed the chanter blank, once again taking care to ensure it was well centred. He then proceeded to bore the chanter blank from the opposite end with a wider drill, occasionally taking it out and cooling the tip a can of liquid; possibly oil or water. Once he reached the half point he used the 4mm drill to reconnect with the original hole. After that he used series of wider drills to create a stepped bore. The conical reaming is done in two stages with flat reamers. The first reamer is under-sized and is used to remove the bulk of the steps in the bore. The second reamer produces the final conical bore. Both reamers are made by him and we talked about how much harder on the tools it is to work with African blackwood. Reaming in Sheesham was hard enough work for the lathe’s ancient electric motor, as it slowed down quite a bit during this whole process. Saeed wanted to know how I did my drilling and I ended up drawing a picture of a gun drill. However I am not sure that even with Ann translating that we fully communicated to him how they work.

Before we left Saeed presented me with one of his new design of highland chanters. 12. I was very touched by this souvenir of our trip to Meerut. He had boxes of chanter reeds and I tried out three and chose the one I liked best in my new chanter. It is well made with a brass folded staple and is far superior to the awful Pakistani ones13. that were sold in UK music shops thirty years ago. The cane is darker in colour than European Arundo Donax and appears to be cut closer to the surface from outer layer of cane. The reed has a more traditional outside profile than is common in most conical bored instrument, and bears little physical relationship to the modern chunky wedge-shaped Highland reed.

It had been such a rewarding visit. We emerged out of Saeed’s dark workshop for a photo session and the friendly and proud owner of the next-door business insisted on giving us a brief tour of his engineering works. It was sad to say goodbye to Saeed and his sons. They were very generous and our connection has been warm and friendly.

Later in the afternoon we walked up Jali Kothi to the shop of the Mehra Brothers Band Company. (That is the name written in Hindi above the shop in Peter’s photo). We showed it to the younger man in the shop who immediately recognised his grandfather and his uncle. I was pleased that eventually we had tracked down this connection and gave him copies of the photos. He told us that they don’t make bagpipes any more, but that they did have one in stock but we didn’t establish who made it. However he explicitly stated that there are no bagpipe makers in Meerut anymore. Judging from Saeed’s indifference to the photo there is obviously some history of rivalry and we thought it best not to mention our visit that morning to Saeed’ s workshop, which is only a couple of hundred yards away.

We left Meerut early next morning; the only tourists in town were leaving! My mind was full of all the questions that I had not asked Saeed. Who makes his reeds? Does he make practice chanters? What bore are they? How does he drill the drone slides? And I wished I had taken many more photos. Is he really the only pipe maker there? I certainly will try to keep in touch with him, but I doubt if I will ever return.

We may never know the exact time that the craft of Highland pipemaking initially took root in the east, but since our visit to Meerut I have engaged in a bit of creative speculation. In the early 1800s in India a Scottish Highland piper in the British Army stumbles, falls and shatters a section of his drones beyond repair. For a regimental piper this is a catastrophe as he is 5000 miles from any Scottish pipe maker. He is told that in ’the native quarter’ there is someone who makes shehnai; an instrument that our piper may never even have even encountered. Clutching his damaged pipes he is shown the way down a maze of narrow street to the local wood turner. The wood turner has never seen such a complex and confusing jumble of pieces of wood in his life, but using his natural ingenuity and his simple bow lathe 14. he eventually finds a way to make an effective replacement out of a local hardwood.

My mission to Meerut had been inspired by Peter’s photos so when I returned to Scotland I phoned him up to tell him how it went. During our conversation, he supplied me with a fascinating snippet of actual historical evidence about early pipemaking in India. Lady D’Oyly (nee Elizabeth Ross) went out to India in 1813 to live with her husband in Patna. At some time in the early 1830s, or perhaps, earlier she commissioned a local craftsman to make a set a set of bagpipes which she sent to her friend, John MacKay 15. of Raasay, piper to the laird of Raasay. We will never know who she commissioned them from or what John thought of them. However I now know that 50 years before Nadir Ali set up his workshop in Meerut at least one Highland Bagpipe had been made in India 700 miles away in Patna.

Notes

- Many years ago I asked a highland bagpipe maker, the late Jimmy Tweedie, whether these pipes were any good and he dryly replied “Aye, they’re are good for putting in the back of the stove”.

- The Brian Boru bagpipe was invented and patented in 1908 by the London Pipe maker Henry Starck and was a development of The Highland pipe. Its most notable feature is the addition of keys on the chanter to increase its range and add chromatic notes.

- The driver explained that the educated and cultured people now call it Kothi Atanas, but everyone else still calls it Jali Kothi.

- We suspect that there might be some in Delhi, Uttrakhand and Rajasthan but Saeed and his sons may well be the last business in Meerut.

- I have seen woodturners in Marrakesh who do very fine turning using a bow lathe and there are obvious similarities to the technique that Saeed uses. The traditional Moroccan bow lathe requires all four of the limbs of the turner, who squats behind the lathe and guides a skew chisel with his left hand and right toe. He powers the lathe with a bow held in his right hand, with the string wrapped around one end of the work piece. Meanwhile he holds the tail-stock in place with his left foot. There are plenty of Youtube videos of Moroccan turners

- Dalbergia sissoo also known as North Indian Rosewood.

- You can watch this on Youtube. http://bit.ly/Chanter35

- In the west pipers regard rubber bags as hopeless as it is important to keep cane reeds reasonably dry in our fairly humid climates. However cane reeds do need a certain amount of moisture to play well, so perhaps in dryer climates the rubber bags may have the advantages to help keeping the reeds from completely drying out? Discuss.

- I assume shehnai makers would have used a bow lathe before the advent of electricity.

- I suspected that most Scottish pipers would find these beads uncomfortable, and that they would certainly restrict the pinkie movements when making a birl, however Callum Armstrong enjoyed playing it briefly and inevitably had no problems playing a birl.

- I videoed the whole process which you can watch on Youtube. http://bit.ly/Chanter36

- I have briefly checked the chanter tuning using the reed Saeed gave me and it appears to play about 20 cents flat of B flat. Callum explored it’s possibilities and found it played an easy top sharpened leading note. He also managed to overblow it to High C and found chromatic notes from High a down to the B. But then he would, wouldn’t he?

- Have they got any better since then?

- I assume it had a similar layout to the traditional Moroccan lathe

- The father of Queen Victoria’s piper Angus MacKay.

Editor’s Note: I was very curious to know whether or not the “improved” chanter actually sounded superior to the one originally obtained all those years ago and I posed Julian the question. His response was: “No idea about that Pakistani chanter from 1979. John gave it to Mum & Dad who took it out to give to me in April 1979 when I was living briefly with my sister in Tokyo. I then gave the set to a nice Dutch guy from Friesland who was called Seebout. I wonder if he eventually put it in the back of the stove?*

- Data Processing Notice (GDPR)

@BagpipeSociety on X (formally known as Twitter)

TheBagpipeSociety on Instagram

BagpipeSociety on Facebook

BagpipeSociety on Facebook

Something wrong or missing from this page? Let us know!