The Bagpipe Society

Notes from a Pandemic Instrument Lab

Traditional music is once again struggling to find a foothold among younger people, but I don’t think it’s for lack of interest. Time and time again at concerts, sessions, and since the pandemic, on my livestream, people have told me how they’ve always wanted to play the bagpipes, flute, or whistle, but didn’t know where to start.

Often the answer would be that they must pay several thousand dollars and wait years just to get a new instrument. The alternative is buying secondhand, often sight-unseen. Someone new to the tradition doesn’t yet have a way to assess the quality or trustworthiness of a transaction like this, and for younger folks, who are squeezed from every possible angle especially in the States, this is an impassable hurdle for all but the most tenacious. For the first six years of my own learning in Irish music, I didn’t have a flute I truly enjoyed playing. I didn’t have a whistle I truly enjoyed playing until I spent a further five years learning to make my own.

When the pandemic first hit, Seattle was a red zone, in strict lockdown for a long time. I started playing the pipes for my neighbourhood every Friday, roaming the grid between 73rd and 80th. People were delighted to have this unexpected diversion, and the chance to safely chat with neighbours and entertain kids provided a lot of mental health support. So too did a newfound interest in Early Music after I caught Rotem Gilbert playing pipes on a Voices of Music broadcast.

Unfortunately, my reed, despite being synthetic, developed a crack, and the spare I got with the pipes did not perform as expected. Despite ordering some more spares from a few different makers and spending many hours of adjustment, I have not successfully been able to duplicate the performance of the first one. Having my favourite instrument be essentially inoperable for nine months was a real blow. I dropped into a few tune classes from the Bagpipe Society, where I asked how they addressed reed problems. The answer was, “I drive up the road to the maker.” Such things are not possible here on the other side of the world, and it became clear to me that I would need to be able to make my own if I was to succeed in this tradition.

Availability of quality instruments and the associated maintenance is a huge problem for learners far from the hotspots for these traditions, yet it’s clear that these far-flung learners are still needed to sustain the community. The hotspots alone aren’t enough (perhaps with the exception of the more institutionalized traditions, like Irish music), and for all the Internet’s ills, we have to embrace the benefits of what our connected world can offer if these traditions are to flourish.

My goal is to address these challenges by designing new takes on traditional instruments which prioritize longevity and durability, with as little maintenance as possible. However, without the benefit of a workshop space or tens of thousands of dollars in equipment, I’m left with the challenge of figuring out how to accomplish this in a 500 square foot apartment.

This is where 3D printing and careful application of the scientific method came in. While developing my pennywhistles, I was only able to visit the community makerspace up north a few times a month, and I was limited to what I could print in only three or four hours. I rapidly had to figure out how to get the most information out of the fewest possible parts, and that skill became the foundation by which I would approach many problems. I often printed designs made of individual parts that could be swapped out to test multiple variables against one another, and developed a production strategy which used automated manufacturing to create a blank, which saves time on the rough work without any need to rush the delicate final finishing. While others stocked up on toilet roll, my panic purchases included a reservation for a Pastoral pipe (in - you guessed it - two years!) and a high-resolution 3D printer. The days of dinner parties with friends now over, I threw away the chairs from my dining table and the workshop was born.

Pennywhistles

Inspired by the vintage Generation-brand whistles like the one my father owned, I created a new whistle design which preserved the attack and crispness the old ones had, while stabilizing the bell note and bringing the second octave in tune. Being that this is a bagpipe periodical, I’ll be brief here, but this project gave me much experience in working with minute tolerances, and troubleshooting many different intersecting variables.

Artificial Reed Cane

Last fall I sent a somewhat random inquiry about materials science to a professor at Carnegie Mellon (since I had found in an article they played traditional music with a composite bow - that was my ‘in’) and I ended up coordinating a team of bagpipe and reedmakers to advise a capstone project by materials engineering students. As this occurred prior to the development of the COVID vaccine, the students were not able to accomplish as much as we would have liked, with limited lab time and access to the equipment. However, the measurements we derived from natural cane as well as some of our proposed alternates have suggested a number of important things. Of the three base fibres we tried (glass, carbon, and hemp), the hemp fibre performed remarkably similar to natural cane, being the closest in density, Tan delta, and Young’s Modulus.

However, despite taking gouges and sandpaper well, the material began to chip at the thicknesses required for the blade tips. Since that paper was published, I have done more research on composites myself, and I think the fibres need to be better-aligned and under tension while the resin is applied, and the entire sheet must be cured under compression. A crude experiment with hardware-store epoxy confirmed that this produces a better material, but I think the best approach will mimic that of the commercial carbon fibre industry - the fibres ought to be soaked in a heat-curing resin rather than a two-part compound, and compressed with greater strength than a few old C-clamps can accomplish.

I’ve still got quite a bit of the fibre used, and am getting some Cactus Juice stabilizing resin, and when I next visit my parents I will avail myself of the much-abused “garage toaster” to test this fully.

More Predictable Reedmaking

The reedmaking process is quite difficult primarily due to the wide gap between the precision required of the final product, and the imprecision of the usual methods employed, requiring a high degree of skill to produce the desired results irrespective of design. Trying to adjust variables or test the effect of different dimensions and materials will inherently produce poor experimental data when the first step is essentially, “tie two brittle flat things to an easily-deformable round thing with nothing but waxed string.”

For me, the first step was confirming that the reed blades were indeed properly aligned and seated appropriately, and that the staple “eye” was of consistent, known dimensions which wouldn’t deform during the process of making and adjusting the reed. Pushing the boundaries of what even my high-resolution printer was able to accomplish, I created a reed staple design which holds the blades in place, and provides parametric inputs to control the dimensions of the eye and final interior diameter. They’re a bit brittle, but should still hold up under normal use.

Following Jon Swayne’s excellent resources, I have made a number of reeds both with these staples and conventional ones, but the process continues to be difficult. Factors such as the tension applied to the string when binding the blades seems to have a significant effect on the final product, and is difficult to control precisely. I’m sure I could come up with a device for this, but since I don’t see it mentioned at all across what I’ve read, I’m sure some other factor is exerting a greater effect over what I’ve made so far.

The biggest difficulty is that once the reed is made, there are few resources suggesting what different sounds and behaviours indicate about it. I have found some basic suggestions for improving a reed that already plays in old issues of The Chanter, but nothing which, for example, might explain why a reed plays well in the lower hand but produces a grating, mechanical squelch in the top hand. I am reading academic papers on the theory of reed design, but much of it is far over my head - Benade can only take one so far in acoustics.

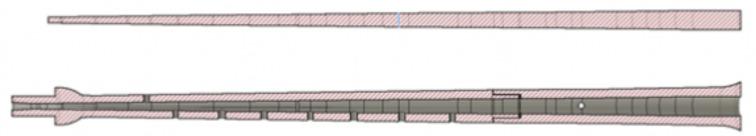

Border Pipes

I’ve succeeded in copying my own Flemish-style G border pipe, and made some improvements by adjusting the cylindrical section beneath the reed seat. The difference between 3.95mm and 3.85mm is really something, adding a lot of sweetness! I am working on adding keywork including a register key and stop key, actuated by tilting T1 and the pad of the top hand, respectively, but am waiting till I can produce a good reed, as further experiments are pointless without seeing how the tone and playability is impacted.

This is a stepping stone to my eventual goal of making convoluted-bore low pipes, which like the Baroque rackett (conical bored) will enable comfortable fingering without sacrifices to tonehole size and other factors. A “pocket border pipe” miniaturizing the original G instrument might be fun, as well.

While FDM (aka plastic wire) 3D printing offers an affordable and durable way to produce an instrument, the tactile feedback and finish are not to everyone’s liking, and can only go so far in aesthetics. I’m keen to try carbon fiber and other composites, as they have excellent acoustics and present a clever way to get around the dreaded need to make custom reamers when developing a new instrument. Instead of printing the bore (or traditionally, reaming it), essentially one creates a negative of the desired bore (easily accomplished through 3D printing or CNC technology), and wraps the material around this mandrel until the desired wall thickness is met. The whole assembly is then heat-cured under compression, and the mandrel removed. This can be accomplished in a standard kitchen oven if one’s landlord is lax on the inspections.

This mandrel approach is particularly attractive because you can inspect it visually and quickly make modifications on the same piece rather than making a new one every time, and it’s a lot easier to measure than the inside of the instrument.

Renaissance Rackett (cylindrical bore)

Recently there’s been a lot of interest among folks I know in the local music community surrounding this instrument. A dear friend (and bandmate in Scottish Gaelic music) is hoping to revive his Renaissance consort, and the rackett is a definite favourite of the possible instruments to include. Another source of interest comes from the more avant-garde circle, who have been incorporating modified reed instruments including a highland practice chanter into some of their pieces, looped through an effects pedal. I, for one, would be very entertained to see the rackett employed for a bassline alongside the electric guitar. So far I’ve been able to find one decent descant model, and a few somewhat- suspect technical drawings of the others, which I might dig into after I get the first one working. The model seems to have come out okay, but again we run into the issue of reeds. I’ve found a paper in French that seems to go into the topic in more detail than most, but it only applies to natural cane, and in a size I don’t have. I’d love to make a synthetic reed at least for the final adjustment of the instrument, even if I end up switching to cane for better tone.

Ergonomic Instrument Supports

Being able to hold and operate an instrument comfortably is pretty much the first step to playing anything, but historical designs did not always have arthritis and tendinitis aforethought when designing their instruments. I’m working on a number of designs which will help support flutes and bagpipes. For the bagpipes, shifting the weight of the front of the bag to the arm rather than the grip makes a big difference for me. Even though a good arm position should support a gentle grip on the chanter, the reality (especially with Flemish-style drones) is that the grip ends up being used to support the weight of the instrument anyway.

The Future

There will always be a market for fine instruments crafted with traditional methods, and far from competing with them, I see my unorthodox designs as helping to grow that market by making these traditions more visible and accessible to the next generation. I have been deeply influenced by the ethos and support of the 3D Bagpipe and Whistle Builder’s Group on Facebook, where makers share designs and museum measurements, others print them and try different experiments, and share their results back with the group.

In line with this practice, I will be sharing the results of my experiments and tests, and open-sourcing as many of my designs and 3D models as I can. Please get in touch with me if you would like to collaborate! I hope to one day leave my day job and make researching and creating new bagpipes, flutes, and whistles my life’s pursuit, along with outreach efforts to grow interest in traditional music.

Cameron Stahl (known professionally by his mother’s surname, St. Louis) is a vocalist and multi-instrumentalist from Seattle, Washington researching and developing new designs for traditional instruments. A graduate of Carleton College, he learned many traditional woodwinds from mentor Laura MacKenzie. Cameron currently works as a senior content manager for a company developing clinical research tools to fight COVID-19. For instrument & research inquiries, send an email to camstlouismusic@gmail.com.

- Data Processing Notice (GDPR)

@BagpipeSociety on X (formally known as Twitter)

TheBagpipeSociety on Instagram

BagpipeSociety on Facebook

BagpipeSociety on Facebook

Something wrong or missing from this page? Let us know!